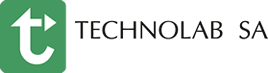

HTST/UHT Mini Pilot Plant

- Availability: On Order

- Brand: Armfield

- Product Code: FT74XA

- Product viewed: 36240

Share:

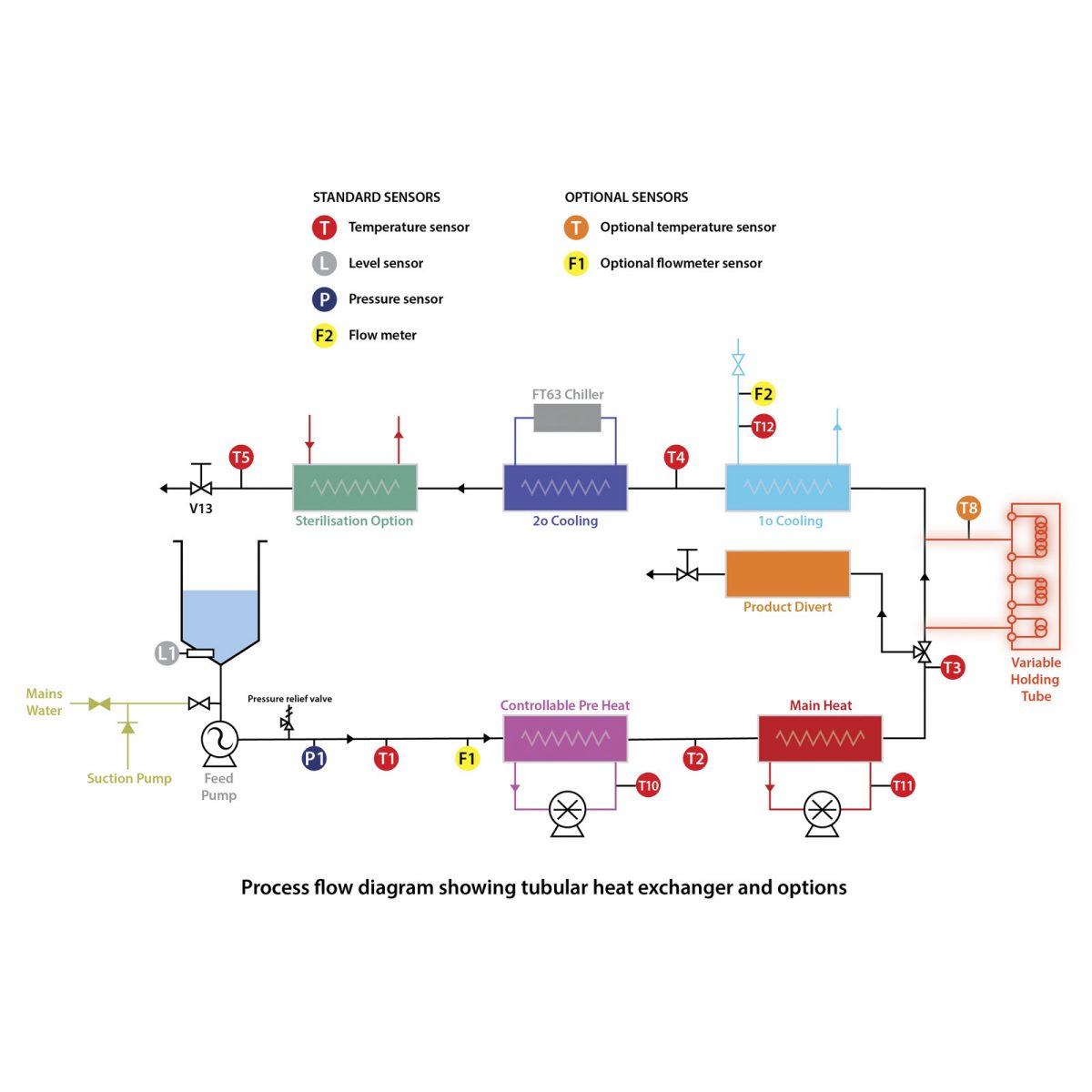

HTST/UHT Mini Pilot Plant with tubular and plate heat exchangers

FT74XA HTST/UHT System

The FT74XA is a highly flexible, miniature-scale HTST/UHT processing system which is ideal for new liquid product development in the laboratory.

It has a wide range of options to suit all needs and can be operated independently or as part of a continuous-operation process with other Armfield equipment.

Description

The FT74XA is compact, mobile and easy to install. It has an integral pressurised hot water generator and requires only electricity and cooling water to operate making it ideal for confined spaces with limited services available.

Operation with either plate or tubular heat exchangers means a wide range of product viscosities can be handled. A progressive cavity feed pump ensures that flow rates are independent of viscosity/backpressure changes and allow a maximum operating pressure of 10 bar.

Cleaning is in place (CIP) utilises the feed pump in high flow rate mode and there is a centrifugal pump CIP option (FT74XA-52) which generates very high cleaning velocities to deal with products that are particularly difficult to clean.

Sterilisation (SIP) of the system is controlled from the touchscreen. System sterilisation time and temperature are defined and key temperature sensors are monitored to ensure the entire system satisfactorily completes the SIP cycle.

Automatic pre-heat control (FT74XA-46) offers an independent hot water circuit and the product pre-heat temperature is set via the touchscreen. The system is well instrumented for both process and services with all sensors displayed on the touchscreen and recorded values can be seen graphically and saved to USB data stick for further analysis.

- The FT74XA base unit provides the heating and cooling services, controls and instrumentation to run the heat exchangers. The heat exchangers fit on top of the base unit and can be interchanged easily in just a few minutes

- All sensor values and set points are shown and input on the screen

- Values can be recorded and extracted at a later date. These data can be viewed in real time as a graph or a table

Applications

- Baby foods

- Beer

- Beverages

- Condiments

- Confectionery

- Milk

- Cream

- Ice-cream

- Yoghurt

- Desserts and puddings

- Fruit and vegetable purées

- Fruit juices and cordials

- Sauces and soups

- Gravies

- Gelatine products

- Pet food

- Health and nutritional products

- Culture media

- Protein drinks

- Pharmaceuticals

Heat Exchangers

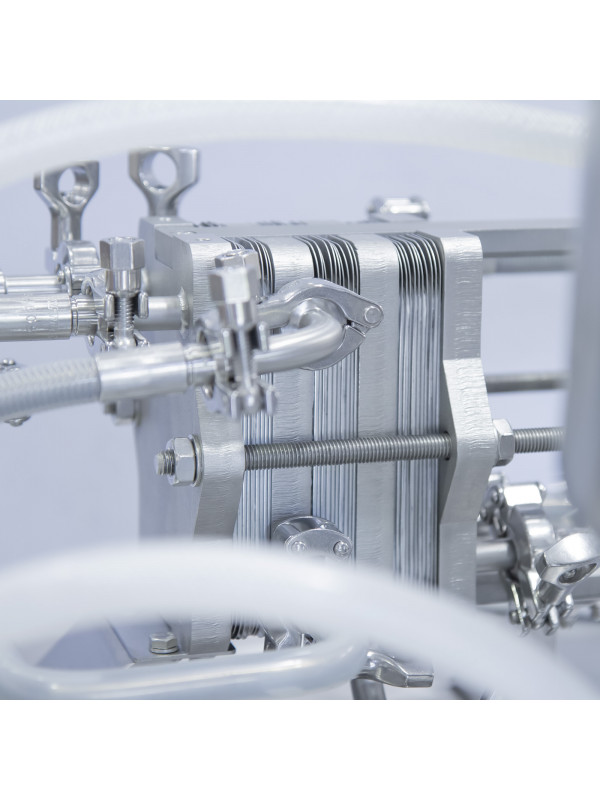

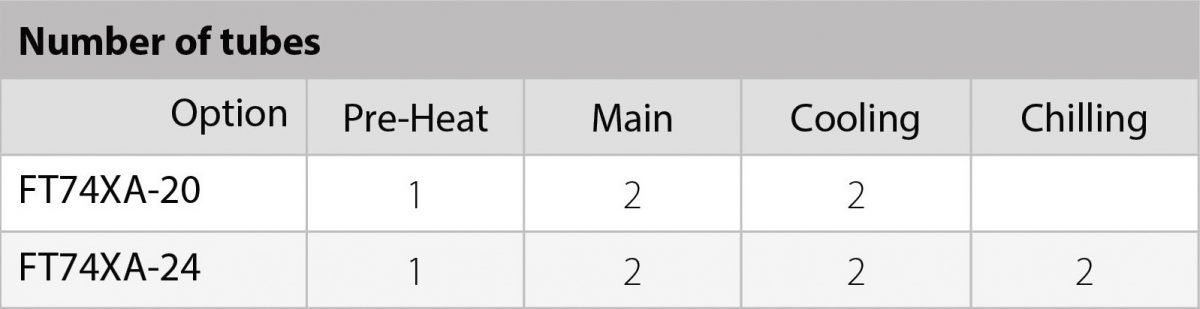

Tubular Heat Exchangers FT74X-20

- Consists of a series of industrial standard 316 stainless steel concentric tubes split into product pre-heat, main heat and cooling stages. With the standard tubular heat exchanger (5 tubes) the product pre-heat temperature is controlled manually using a needle valve to control hot water flow

- Product flows down the middle of the inner tube and the heating or cooling medium flows counter-currently through the anulus

- The surface area for cooling can be doubled by specifying the -24 option

- A double area heat exchanger (10 tubes) is available

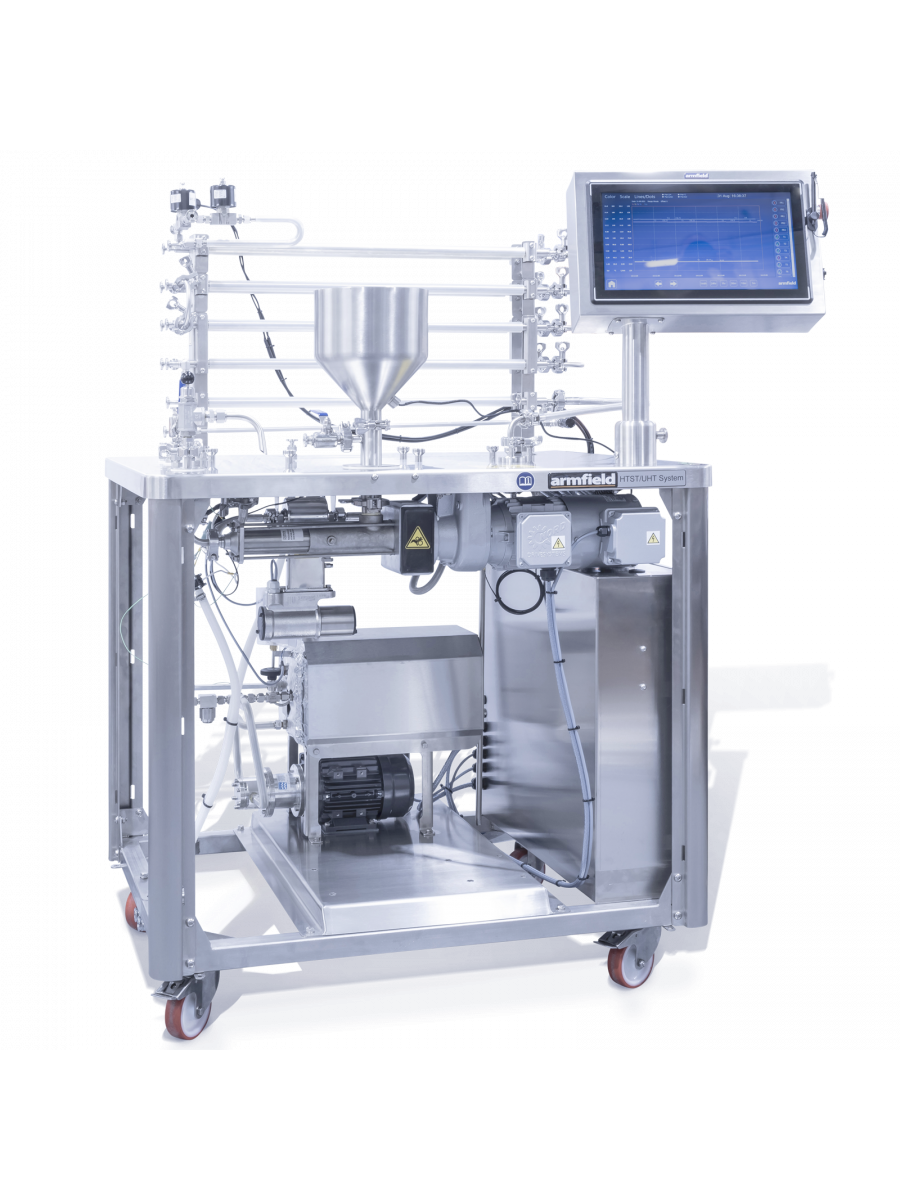

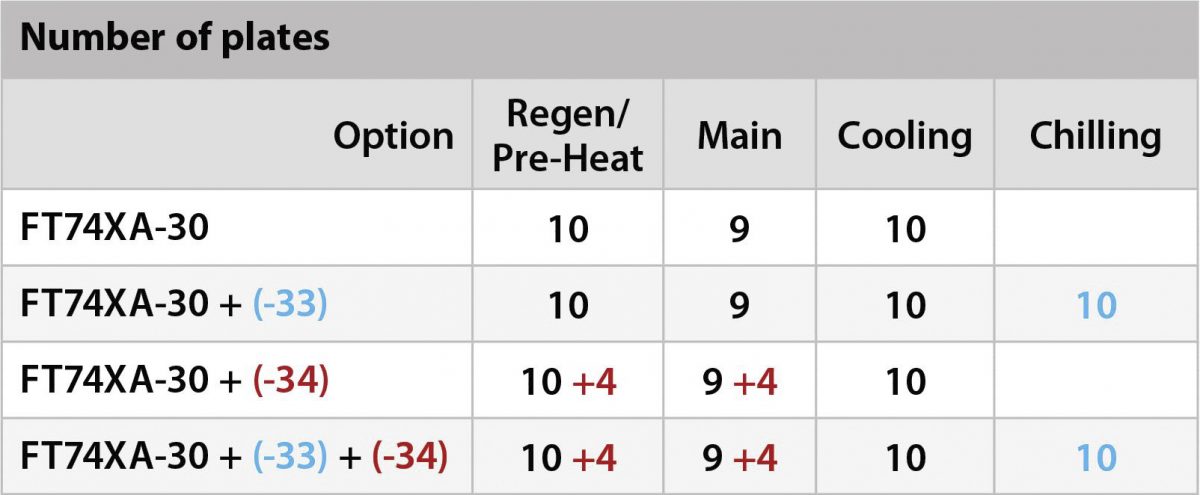

Miniature Plate Heat Exchanger FT74XA-30

- The standard FT74XA-30 has a regeneration section that uses heat from hot product to heat incoming product. There is also a main heat and cooling stage. A number of options can be added:

- FT74XA-31/32 Homogeniser plate upstream (-31) of main heat and downstream (-32) of main heat

- FT74XA-33 Dual stage cooling gives an extra cooling stage (can be serviced by Armfield FT63 recirculating glycol chiller) to enable very low (< 5°C) product outlet temperatures

- FT74XA-34 provides extra plates in the pre-heat and main heat sections which can be beneficial when operating at higher product flow rates for pasteurisations

Associated Equipment

A wide range of equipment is available for use in conjunction with the FT74XA system to enhance the overall processing capability.

- FT90/91 Homogenisation Subsystems

- FT83 Sterile Filling System

- FT63 Process Chiller

- FT140 Mixing Vessels

- Integrated systems

In addition to our standard offering, Armfield offer a service to design and build complete bespoke integrated processing lines optimized to your specific requirements.

Options to Eenhance Functionality

- Suction feed (FT74XA-41/53) – These two options allow the unit to be connected to a feed tank instead of the hopper (-41). An automated valve is used to add water when product runs out (-53)

- Product divert valve (FT74XA-22) – maintains downstream sterility when main heat temperature drops bellow the set point

- Pneumatic pinch valve (FT74XA-42) – for use with products that contain particulates

- Equipment Sterilisation Option (FT74XA-45) – this enables the FT74XA to provide sufficient heat to sterilise the Armfield FT83 sterile filler

- Variable holding tube (FT74XA-65) – This comprises three separate holding tubes mounted inside an insulated stainless steel housing. The coils, used independently or in conjunction, provide seven different holding times between 30s and 120s at 10 L/h. Intermediate holding times are possible by varying the product flow rate

- Electromagnetic product flow meter (FT74XA-40) – with readings data logged

- Controlled Cooling (FT74XA-51) – control the final temperature with a desired set point

- CIP System (FT74XA-52) – Clean with high velocity for especially fouling products

Requirements

- Electricity supply: Single or Three phase (see ordering codes)

- Water supply: Required for product cooling, typically 5 l/min (or FT63 Process Chiller)

Shipping Specifications

Packed and Crated Shipping Specifications

Volume: 2.1m3

Gross weight: 380kg

Dimensions

Length: 1.01m

Width: 0.72m

Height: 1.45m

Order Numbers

- FT74XA-A: 220-240V/1ph/50Hz (40A max)

- FT74XA-E: 400V/3ph/50Hz (25A max)

Technical Specifications

FT74XA Heat Exchanger Service UnitFeed Pump

Progressing cavity variable-speed pump, with standard and high flow modes.

Particulate handling: 0.8mm

Fibre handling: 25mm

Standard flow: 10-30 l/hr

High flow: Up to 120 l/hr

Pressurised Water Circulator

Water capacity: 4.0 litres

Pump circulation rate: Variable up to 6 l/m

Water temperature: 165˚C maximum

Safety cutouts:

- Low Level

- High Pressure

- Mechanical Pressure Relief Valve

Plate Heat Exchangers

Plate overall dimensions: 75 x 115mm

Effective diameter: 2.0mm

Plate thickness: 0.5mm

Wetted perimeter: 153.0mm

Materials

Plates: 316 stainless steel

Gaskets: Food-grade silicone

Working pressure: 10 bar (max)

Standard holding tubes: 2s and 15s

Tube Diameter

(product side): 8.1mm

Overall diameter: 15.8mm

Length (heated): 800mm

Material: 316 stainless steel

Assembled test pressure: 15 bar

Working pressure: 10 bar (maximum)

Standard holding tubes: 2s and 15s

Features & Benefits

- Touchscreen control of all operations (15 inch)

- Tubular and plate heat exchanger options with rapid switch over

- Low product hold-up

- Variable holding tube option (FT74XA-65)

- High accuracy temperature sensors (PT100)

- Fully instrumented

- Upstream and downstream homogenisation

- Aseptic and non-aseptic modes

- Automated SIP option

- On-screen calculation of holding times and Fo value based on holding time and temperature

- Controlled cooling on the outlet (option)

- Recipes system as standard

- Two-stage cooling option

- Backpressure control using a sprung diaphragm valve or pinch valve (FT74XA-42) for products containing particulates

- Suction feed options for increased automation and batch size