Rising Film Evaporator

- Availability: On Order

- Brand: Armfield

- Product Code: FT22

- Product viewed: 62231

Share:

Rising Film Evaporator

The Armfield Rising Film Evaporator is a floor-standing unit, designed to provide practical training for the operation of large modern evaporator equipment in industry.

Description

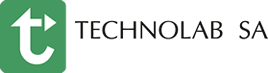

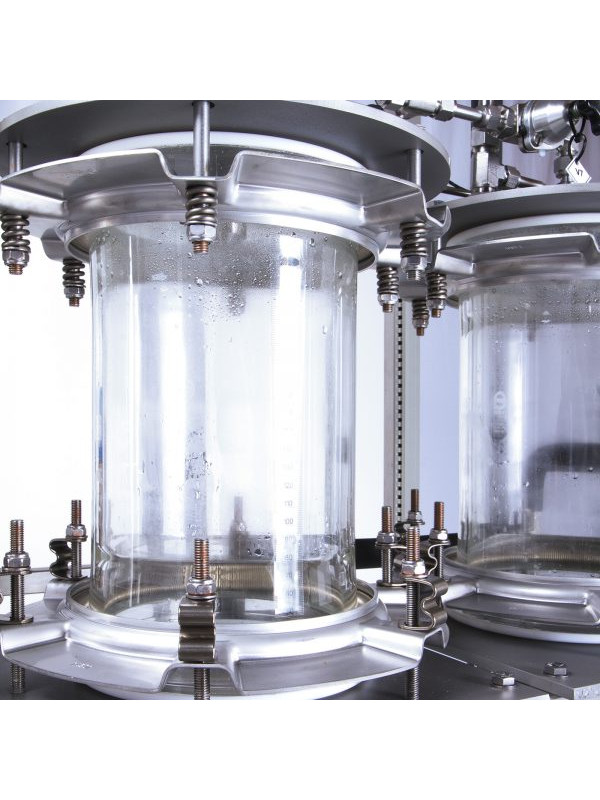

The single tube-in-jacket evaporator replicates industrial units which often contain scores of much longer tubes within the steam space. The component parts of the industrial process have been scaled down, feed tank, vapour/liquid separator, condenser, concentrate tank, condensate tank, CIP pump and vacuum pump, all manufactured from hygienic materials such as stainless steel, PTFE and glass.

The system is supported within a stainless steel framework and requires only a connection to suitable steam, electrical and water services for operation.

Only 0.65m² of floor space is required to install the evaporator and it has been designed to fit easily into a room of standard height.

Demonstration capabilities

- Juices (fruit and vegetable)

- Milk and milk products

- Extracts (non-flammable)

- Effluents

Technical Specifications

Evaporator tube length: 1.36m

Heat transfer area: 0.06m2

Max evaporation rate: 10 l/hr

Max steam consumption: 15 kg/hr

Max steam pressure (working): 1.7 bar

Condenser area: 0.17m2

Feed tank capacity max: 30l

Concentrate collecting tank capacity: 5l

Condensate collecting tank capacity: 5l

CIP pump (flexible impeller): 8 l/min @ 20ft H2O

System vacuum: 225mm Hg ABS (increased when pump heads in series)

Features & Benefits

- Small quantities of liquid products can be concentrated

- Easily cleaned and maintained

- Low product usage eases the disposal of waste

- Nominal throughput only 10 l/hr

Features

- Single-tube heat exchanger

- Integral CIP system

- Integral control console

- Data logging and analysis included

Accessories

UOP10 Steam Generator

Provides an adequate supply of steam as the heat transfer medium.

Electricity supply

FT22-A: 220-240V / 1ph / 50Hz / 3kW

Data logger: A computer runing Windows 98 or above, with a USB port.

Shipping Specifications

Volume: 2.40m3

Gross weight: 330kg

Dimensions

Height: 2.60m

Width: 0.78m

Depth: 0.65m