Batch Solvent Extraction and Desolventising Unit

- Availability: On Order

- Brand: Armfield

- Product Code: FT29

- Product viewed: 29988

Share:

Batch Solvent Extraction and Desolventising Unit

FT29 Batch Solvent Extraction and Desolventising Unit

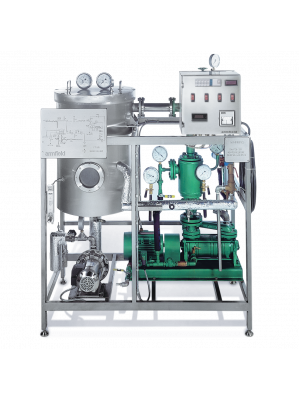

The Armfield Batch Solvent Extraction and Desolventising Unit is a floor-standing, batch process unit capable of carrying out a variety of solid/liquid extractions. It is particularly suitable for 'leaching' edible oils from oil-bearing seeds and desolventising both the extracted solids and the miscella.

Features

• Fully self contained system

• Floor Mounted

• Single extraction/desolventiser vessel

• Miscella tank

• Tops condensor

• Solvent/water recovery tank

• All flame proof construction

Benefits

> Operation of small-scale version of industrial processes

> A wide variety of solid/liquid extractions may be processed

> Small quantities (25 kgs) can be processed

> Low disposal rates

Description

All vessels, pipes, valves and fittings in contact with process materials are constructed in stainless steel with the exception of the borosilicate glass solvent condenser. The support framework is also stainless steel.

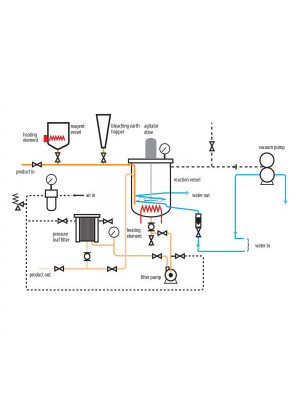

Schematic diagram

of the FT29

enlarge

enlarge

The cylindrical extractor/desolventiser with a hinged lid for charging the extraction material, has a base inclined slightly towards a port for discharging the extracted and desolventised meal. Material is supported above the base by a perforated plate covered with a fine woven mesh so solvent may drain through to the miscella tank whilst retaining the solids. The vessel base is equipped with an indirect steam chest for process heating. Direct steam is injected at a variable rate through a distribution pipe positioned above the mesh. A similar distribution pipe positioned near the top of the vessel allows solvent to be sprayed uniformly onto the bed of material. The miscella tank, positioned directly below the extractor to collect the draining liquid, is also a cylindrical vessel incorporating a steam chest as its base.

This vessel also incorporates a direct steam distribution pipe through which steam can be metered at a variable rate. Vapour from the vessels, produced in the desolventising process,is directed by ducting to the solvent condenser, an inclined cylindrical glass tube containing a double coil through which cooling water is circulated. Condensate (usually a mixture of solvent and water) drains into the solvent water separator tank which allows thorough separation of the solvent and water by a gravity process.

(Note: Only hexane or solvents having a similar specific gravity can be effectively separated in this tank).

Solvent reclaimed from this vessel can then be recirculated by the solvent pump at a regulated rate through a variable area flow meter. Excess water overflows to a waste water tank from where it can be disposed of on completion of the process. Operation at reduced system pressures are achieved by a PTFE diaphragm type vacuum pump. The outlet of this pump is piped through a flame arrester to a suitable ventilation point. Each vessel is equipped with suitable level/sight glasses so that the processes can be observed and monitored. Pressure and temperature gauges are supplied where necessary as are adequate sampling and drain valves.

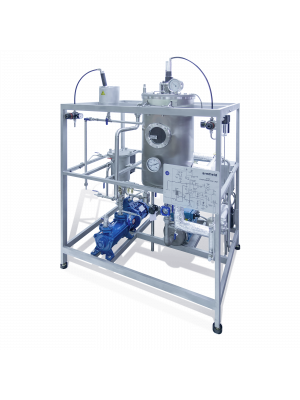

Inspecting the interior of

the extractor vessle

enlarge

enlarge

Hexane is the most widely used solvent in the extraction process and, due to the inflammable nature of this product, electrical equipment has been kept to a minimum. Where electrical equipment must be used, it is specified to the appropriate standards for safety.

The main processing vessels have been designed in accordance with the appropriate code of practice for welded pressure vessels.

Modes Of Operation

Extraction by Recirculating Miscella

This

involves priming the miscella tank with clean solvent then pumping the

solvent to the extractor where it percolates through the material bed

and drains as miscella back into the tank for recirculation.

Extraction by Washing with Clean Solvent

As

miscella is formed, steam admitted to the miscella tank base causes

solvent to evaporate. The vapour is condensed in the solvent condenser

and returns to the separator tank from which it is pumped back to the

extractor.

Desolventising Extracted Material

When

the extraction is complete, the static hold-up of solvent remaining in

the material must be removed and this is achieved using a combination of

direct and indirect steam and vacuum. The solvent vapourises and is

condensed along with the direct steam and the condensate. The mixture of

solvent and water is separated in the solvent water separator tank.

When the extracted material is free of solvent it is discharged through

the door at the base of the extractor.

Desolventising Miscella

Miscella is a

mixture of the solvent and oil from the extraction material which

accumulates in the miscella tank during the process. The solvent and oil

are separated in a similar method as for material desolventising using a

combination of direct and indirect steam and vacuum.

A higher level of vacuum is required than for material desolventising in order to produce solvent-free oil.

Within each mode of operation, many operating parameters such as process temperature, solvent temperature, solvent flow rate, direct steam flow rate and system pressure can be adjusted to allow a high degree of experimentation.

Some Examples of Extractions Possible Using the FT29

| Extraction material | Extract | Solvent |

|---|---|---|

| Oilseeds/presscakes | Edible oil | Hexane |

| Tree bark | Tannin | Water |

| Solanium (a grass) | Steroid | Dil. sulphuric acid |

| Pyrethrum flower | Insecticide | Hexane |

| Tea leaves | Tea | Water |

| Wheat germ | Oil | Hexane |

| Rice bran | Oil | Hexane |

| Poppy stalks | Morphine | Water |

| Flowers/fruits | Essential oils | Hexane |

| Liquorice roots | Liquorice juice | Water |

Capabilities

> effect of degree of pretreatment of solid material on extraction efficiency

> effect of solvent type

> effect of solvent percolation rate

> effect of process temperature and pressure

> effect of extraction time and drain time

> method and degree of solvent recovery.

Unit Specifications

Extractor Vessel:

Volume: 100 litres

Batch capacity: 25kg based on density of 560kg/m3

Direct steam: 0 - 7 kg/hr

Indirect steam: 0 - 3.5 bar

Miscella Tank:

Volume: 30 litres

Minimum extract: 2 litres

Direct steam: 0 - 4kg/hr

Indirect steam: 0 - 3.5 bar

Solvent Condenser:

Condensing capacity: 2.5kW

Condensing area: 2.5m2

Cooling medium: water

Cooling water flow range: 0 - 22 l/m

Solvent Water Separator Tank:

Volume of separator section:16 litres

Volume of solvent store section:16 litres

Waste Water Tank:

Total volume: 15 litres

Vacuum Pump:

Type: Double PTFE diaphragm

Drive: Flameproof a.c. motor

Operating pressure: 100mbar (max).

Solvent Pump:

Type: Gear

Drive: Flameproof a.c. motor

Solvent flow range: 0-8lpm with by-pass flow control.

Requirements

Electricity

FT29-C: 415V/3ph/50Hz, (0.6kW)

FT29-D: 208V/3ph/60Hz, (0.6kW)

FT29-E: 380V/3ph/50Hz, (0.6kW)

FT29-F: 220V/3ph/60Hz, (0.6kW)

Cooling Water

25 l/m @ 3.0 (min) - 5.0 (max) bar pressure.

Steam Supply

20kg/hr @ 5.0 bar min. pressure

Shipping Specification

Overall volume: 5.8m³

Overall weight: 880kg

Overall Dimensions

Height: 1.75m

Width: 1.90m

Depth: 0.90m