Sous-systèmes Homogénéisation

- Disponibilité: Sur commande

- Marque: Armfield

- Code produit: FT90/FT91

- Produit vu: 83710

Partager:

Sous-systèmes Homogénéisation

MINIATURE-SCALE R&D TECHNOLOGY

FT90/FT91 Sous-systèmes Homogénéisation

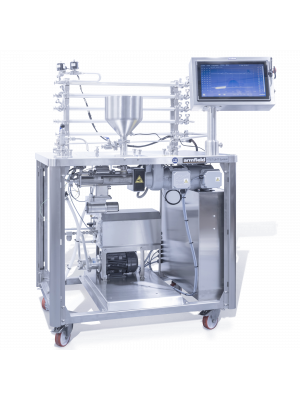

Le FT90 et FT91 sont des sous-systèmes complets d'homogénéisation en ligne pour utilisation avec Armfield équipements agroalimentaire à échelle miniature.

The FT90 is based on an APV 1000 homogeniser and the FT91 is based on a Niro Twin Panda.

Both homogenisers have been specifically optimised for this application.

The units include controls, comprehensive instrumentation, valves, pipework, pulsation dampers, datalogging and all facilities required for operation and process integration with other Armfield equipment.

Features

• Complete Homogenisation Subsystems

• Configurable for upstream or downstream homogenisation

• Variable throughput

• Two Stage Homogenisation with adjustable pressure (1000bar FT90, 600 Bar FT91)

• Twin Pistons (FT91) or Single Piston (FT90)

• Pulsation Dampers included

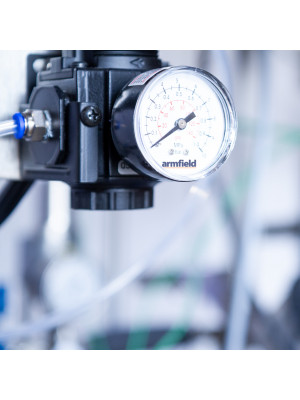

• Comprehensive instrumentation includes product temperature, product line pressure, homogenisation pressure and pump speed.

• All these parameters are displayed on the control console and available for datalogging via the integral USB datalogger

• Datalogging software seamlessly integrates the data with the data from the FT74X/FT74XTS or similar.

• Adjustable divert facility for easy integration into continuous flow processes.

• Complete with interconnection hoses

• Can be sterilised and used in an Aseptic system

Benefits

> In-line homogenisation for trial quantities and miniature-scale processing

> Simple integration with existing Armfield plant

> Uses scale-down valve technology which ensures the results are representative of production scale processing

Description

These units have been specifically developed to provide a simple and complete solution for in-line homogenisation in conjunction with the Armfield FT74X/FT74XTS range of miniature-scale processing equipment. They contain the homogeniser, pulsation dampers, a stainless steel control cabinet plus the required control valves, pipework and instrumentation all mounted within a stainless steel frame.

Hand wheel adjustment is provided for both stages of homogenisation pressure. The homogenisation pump speed is electronically controlled from the control console, and a manually adjustable divert valve is used to compensate for any inequalities between the flow rate from the FT74X/FT74XTS and the homogeniser, or any fluctuations in these flows.

The homogenising valves, and the seats and balls of the pump valves, are manufactured from a hard wearing ceramic material, stellite. The pulsation dampers are located upstream and downstream of the homogeniser to provide smooth flow on both sides. The pulsation dampers are non-pressurised and can be easily dismantled for cleaning.

The stainless steel control console includes displays for the homogenisation pressure (both stages on FT90), for product temperature and for product process pressure. The outputs from all the sensors, together with the pump speed are also made available on an integral USB interface. The software provided with the FT90 and FT91 allows this data to be fully integrated with that from an FT74X/FT74XTS datalogger, with a single display screen, single data table, and options to graphically display any or all of the data from either system.

The FT90 and FT91 are supplied with all necessary equipment, interconnecting hoses, homogeniser tools etc. for trouble free integration and operation.

Unit Specifications

| Unit | FT90 | FT91 |

|---|---|---|

| Homogeniser | APV 1000 | Niro Twin Panda 600 |

| Throughput: Adjustable | 8-22 l/hr | 10-30 l/hr |

| Max 1st stage Homogenisation Pressures | 1000 bar | 600 Bar |

| Homogenisation Temperature | 105°C max | 90°C max |

| Max Sterilisation Temperature (30 mins) | 130°C | 140°C |

| Pump Power | 3 kW | 1.5 kW |

| No of pistons | 1 off | 2 off |

Requirements

Electricity:

FT90-E 380-415V/ 3ph/ 50Hz 3.5 kW

FT90-F 220V / 3ph / 60Hz 3.5 kW

FT91-A 220-240V / 1ph / 50Hz 2kW

FT91-G 230V/ 1ph / 60Hz 2 kW

Water or Steam for lubrication (FT90 only)

Steam (sterile operation only)

Required Accessories

A PC running Windows 98 or later with an unused USB interface is required for datalogging. (If being used with FT74-44 or equivalent, two USBs are required).

For use with FT74-30MkIII, a homogeniser interconnection plate must be used. FT74-31 is used for upstream homogenisation (homogenisation during heating) and FT74-32 is used for downstream homogenisation (homogenisation during cooling).

Shipping Specification

FT90

Volume: 1.8m3

Gross Weight: 238kg

FT91

Volume: 1.8m3

Gross Weight: 240kg

Overall Dimensions

FT90

Height: 1.42m

Width: 1.13m

Depth: 1.10m

FT91

Height: 1.42m

Width: 1.13m

Depth: 1.10m