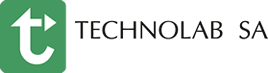

Système de Remplissage Stérile

- Disponibilité: Sur commande

- Marque: Armfield

- Code produit: FT83

- Produit vu: 63773

Partager:

Système de Remplissage Stérile

MINIATURE-SCALE R&D TECHNOLOGY

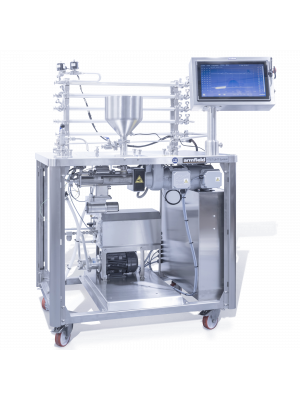

FT83 Système de Remplissage Stérile

L’Armfield FT83 est la solution la plus économique pour les départements R & D pour produire des échantillons stériles emballés avec une excellente durée de vie. Ainsi que d'un espace de travail avec un environnement stérile et contrôlé, l'unité comprend les installations pour permettre de stériliser tous les chemins de produits et de contrôler d'une manière simple le remplissage.

Features

• Capable of filling containers and producing sterile samples

(when linked to a suitable UHT processing system)

• Filling environment to ISO class 5

(i.e. meets microbiological safety and pharmaceutical production/filling requirements)

• Simple operation

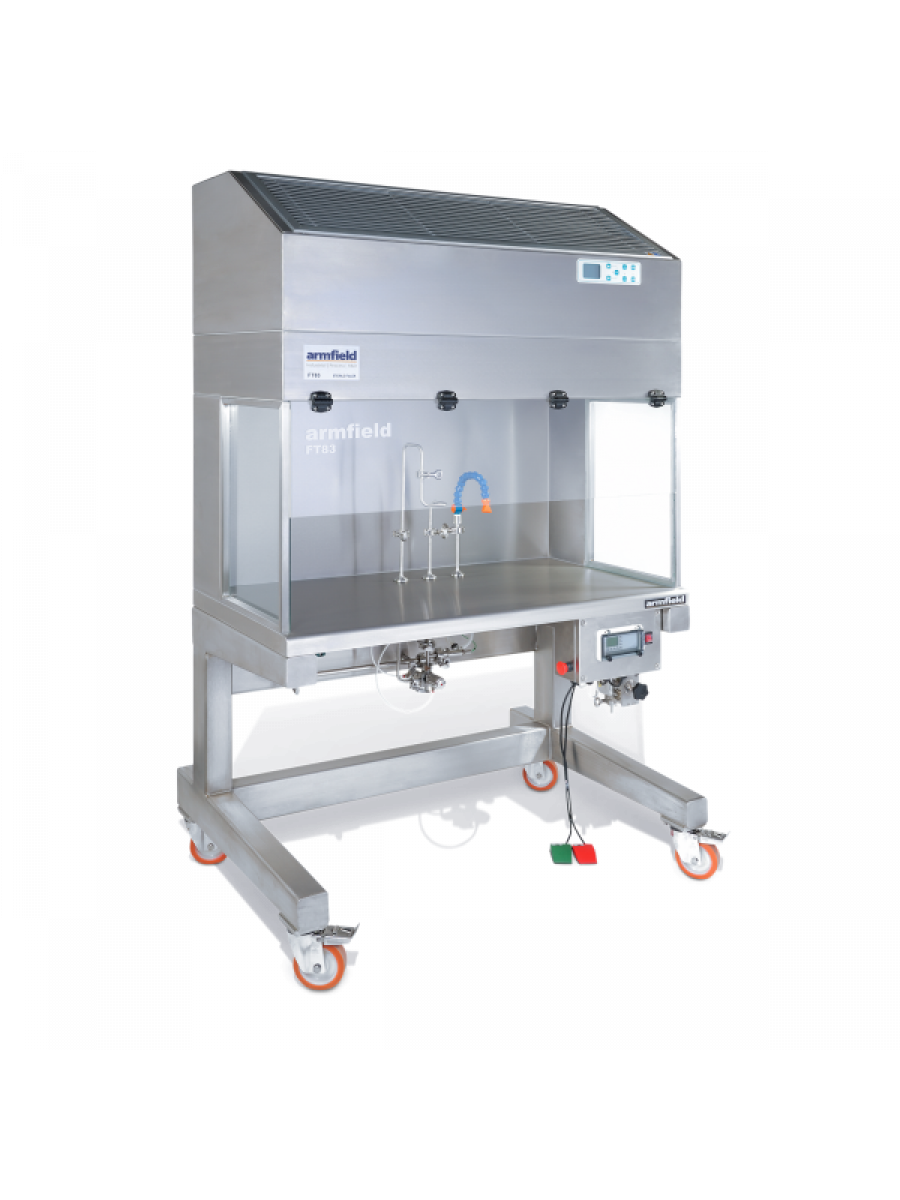

• Open front for ease of use

• Large working area

• Wide range of containers and sealing devices can be catered for

• Low Oxygen Filling facility as standard

• Can form part of a complete aseptic UHT processing line

• Cleaning, Sterilisation and Filling modes

• Stainless Steel Construction

Benefits

> Extended shelf life products achievable

> Can interface with existing Armfield UHT equipment

Description

The FT83 utilises a vertical flow laminar flow cabinet to maintain the air within the working section to better than ISO Class 5 (Federal Standard 209e - Class 100). This high specification is achieved by passing the air through a high efficiency HEPA filter, and recirculating most of this air to get an improved filtering effect. A digital air flow readout is incorporated and also serves as a warning when the HEPA filter needs replacing. A pre-filter extends the life of the HEPA filter.

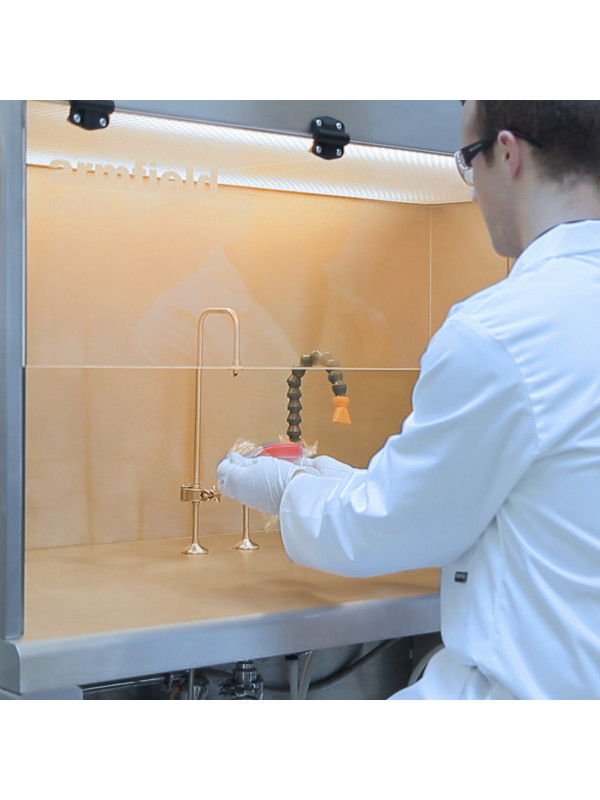

The product from the UHT system is either passed to the filling head or diverted to drain by means of a hygienic, pneumatically operated, three way valve controlled by a foot pedal. When filling, the operator places a pre-sterilised container under the filling head and uses the foot pedal to fill to the required level.

When cleaning-in-place (CIP) or sterilising-in-place (SIP) a stainless steel pipe is positioned over the filling head to a return outlet in the working chamber. The cleaning fluid or sterilising hot water can be passed through the filling head, and also through the divert section. In these modes the integral mini-plc now controls the 3-way valve and hence the flow path. During SIP the plc also monitors the temperature of the water to ensure that the specified sterilisation time and temperature have been met.

The flow path to drain incorporates a heat exchanger to reduce the sterilising water to a safe temperature and a back pressure valve to maintain pressure within the system to prevent boiling.

The containers used for filling need to be sterilised before use. Any convenient sterilisation method can be used, such as autoclaving, gamma radiation, or buying in sterilised containers from a laboratory equipment supplier. In use, the working chamber is cleaned manually.

The cabinet surfaces are sterilised using a suitable spray (e.g. ethanol).

This method can also be used to sterilise the neck and seal of the containers where necessary. Filled containers can be removed easily from the working chamber and new containers can be introduced without introducing product contamination. Trials have shown that using this system, new operators with a minimum of instruction can produce packaged aseptic samples similar to production aseptic filling systems.

A nitrogen nozzle is included, which can be directed over the container whilst filling, to give low oxygen content in the packaged product.

FT83 Specifications

Air quality inside chamber: Federal Standard 209e - Class 100 ISO 14644 Class 5

HEPA filter efficiency: 99.995% at 0.3 Micron EN1822 – H14

Working Chamber Size: 1220mm x 580mm

Ordering options

The standard FT83 incorporates its own PLC which controls the sterilisation process described above.

The FT83-94 is designed for use with the Armfield FT94X UHT system.

The FT83-94 is controlled from the FT94X PLC giving the operator the advantage of a single touch screen interface with the whole system.

Requirements

Electricity (single phase):

FT83-A, FT83-94A 220-240V, 50Hz

FT83-B, FT83-94B, 110-120V, 60z

FT83-G, FT83-94G 220-240V, 60Hz

Compressed Air:

5-7 bar

Cooling Water Supply:

5l/min at 1 bar, max. temperature 25°C

Nitrogen Gas:

Only needed for low oxygen filling

UHT System (for sterilisation):

Either FT74XTS plus FT74-45, or FT94X

Shipping Specification

Volume: 4.5m³

Gross weight: 400kg

Overall Dimensions

Height: 2.2 m

Width: 1.3 m

Depth: 1.1m